The main purpose of the EN ISO 11683 standard is to ensure that people with visual impairment or inability to use visual information can safely use products containing hazardous substances or preparations. By providing tactile warnings, these users can identify and understand hazardous information on packaging without relying on visual cues, and take appropriate preventive measures.

This standard is widely used on packaging containing hazardous substances or preparations, such as chemicals, drugs, fireworks, and firecrackers. Manufacturers must comply with these regulations to ensure the safety and compliance of their products. At the same time, regulatory agencies will also supervise and inspect products on the market based on these standards.

The EN ISO 11683 standard provides detailed requirements for tactile warnings of hazards on packaging, including but not limited to the following aspects:

The format and design of warnings: The standard provides detailed instructions on how warnings should be designed and formatted to ensure that they can be understood by people with tactile perception. The warning should be clear, concise, easy to understand, and use tactile sensitive fonts, patterns, or textures.

Warning location: The standard specifies where warnings should be placed on the packaging to ensure they are easily accessible and recognizable. Usually, these warnings should be located in prominent positions on the packaging, such as the top, side, or bottom, so that users can easily recognize them before use.

Warning language and information: Standards require that warnings should contain clear, specific, and accurate information describing the types, degrees, and possible consequences of hazards present in the product. These pieces of information should be presented in a tactile sensitive manner, such as through raised letters, numbers, or symbols.

Testing method: The standard also provides testing methods to ensure that tactile warnings produced by manufacturers comply with regulations. These tests may include physical testing (such as wear resistance, weather resistance, etc.), information testing (such as recognition, understanding, etc.), and user testing (such as usability, satisfaction, etc.).

Standard interpretation:

1. Scope of application:

Dangerous tactile warnings are only affixed to packaging covered by current regulations for hazardous substances and preparations.

Dangerous tactile warnings should be placed on the packaging so that they can be felt before fully opening the package.

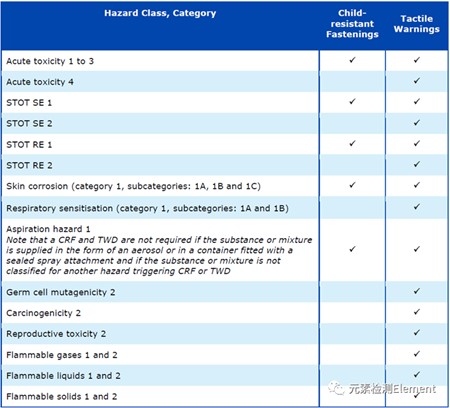

Containers containing substances or mixtures classified as follows that are intended for public use must display a hazard tactile warning (some classifications may also require child proof opening design)

-Acute Toxicity 1-4- Oral (H300, H301, and H302), Skin (H310, H311, and H312), or Inhalation (H330, H331, and H332)

-Skin Corrosion 1, Subcategory 1A, 1B, and 1C (H314)

-Genital cell mutagenicity 2 (H341)

-Carcinogenicity 2 (H351)

-Reproductive toxicity 2 (H361)

-Respiratory Allergies 1, 1A, and 1B (H334)

-STOT SE 1 or 2 (H370, H371)

-STOT RE 1 or 2 (H372 and H373)

-Inhalation hazard 1 (H304).

-Flammable gases 1 and 2 (H220 and H221)

-Flammable liquids 1 and 2 (H224 and H225)

-Flammable solids 1 and 2 (H228)

2. Symbol requirements: including regular symbols and three symbols of reduced size: 9mm symbols, 3-point symbols, and 3mm symbols. The selection order is regular symbols → use 9mm symbols only when the application of regular symbols is impossible → use 3-point symbols only when the application of 9mm symbols is impossible → use 3mm symbols only when the application of 3-point symbols is impossible 2.1 Regular symbols

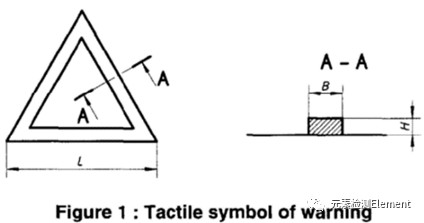

It is an equilateral triangle with sharp edges as much as possible (see Figure 1). The edges on the corner should be connected where feasible, and if not, the distance should not exceed 1.0 millimeter

The length L of the edge is 16-20 millimeters

The triangle consists of a frame with a width B ranging from 1.5 millimeters to 1.9 millimeters

The height H (protrusion) of the frame cross-section should be between 0.25 millimeters and 0.5 millimeters

The minimum area of the frame cross-section should be 1/2 H x B

The shape of the cross-section can be rectangular (see section A-A in Figure 1) or curved

2.2 Three Reduced Sizes 2.2.1 9mm Symbol This symbol is an equilateral triangle, with the same requirements as conventional symbols except for the following points

The side length L is between 8mm and 10mm

This symbol can be a frame or filled in

When there is only a frame, the width B of the triangle should be between 0.8 millimeters and 1.2 millimeters

If the triangle is filled (solid), then the height and contour around it are the same as the frame's specifications.

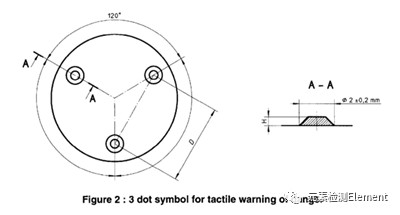

2.2.2 Three point symbol

Three points - each in the shape of a truncated cone - should be arranged equidistant on a circle (see Figure 2)

The diameter of each point should be between 1.8 millimeters and 2.2 millimeters

The height H (protrusion) of this part should be between 0.25 millimeters and 0.5 millimeters

The distance between any two points D - center to center - should be equal and between 3mm and 9mm

2.2.3 3mm symbol

A triangle should be an equilateral triangle with sharp edges as much as possible (see Figure 1)

This symbol should be solid

3mm≤L≤4mm

The height H of the protruding part should be between 0.25mm-0.5mm

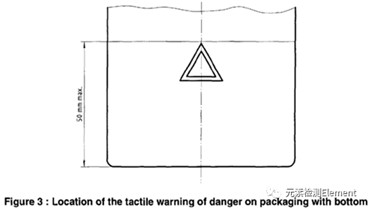

Location of 3 dangerous tactile warnings

3.1 General requirement: The location of the danger tactile warning should not cause confusion with any other embossed patterns.

3.2 Packaging with Bottom 3.2.1 Generally, it is required that the complete symbol of each hazard tactile warning be located on an upright processing surface near the edge within the enclosure shown in Figure 3, with the top of the triangle no more than 50 millimeters away from the bottom of the container.

3.2.2 Specific Cases 3.2.2.1 General Requirements: For the following containers, unless technically impossible, tactile warnings of danger should be set according to the following regulations. If not feasible, follow the requirements of 3.2.1. 3.2.2.2 The packaging hazard tactile warning for aerosols should be located on the surface of the aerosol packaging, where fingers are used to activate the aerosol. The surface (start button or spray cap) is an integral part of the aerosol packaging and will not be removed during normal use of the product. 3.2.2.3 Combustible gas containers are gas containers whose contents can only be used when connected to specific connectors or fittings, and the tangible features of these connectors or fittings are considered as tactile warnings of danger. For sealed gas containers with a top shape that complies with EN417 regulations, the tangible features of their shape are considered as tactile warnings of danger. 3.2.2.4 Fully opened plastic packaging (injection molding process)

The tactile warning should be located on the operating surface, as close as possible to the opening.

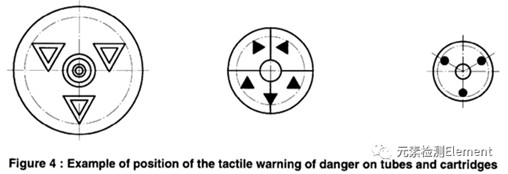

3.3 Bottom less packaging: For pipes and tubes, tactile warnings should be located on the shoulders and evenly distributed around the pipe mouth, as follows: circular dots and triangles are distributed on concentric circles around the pipe mouth; They are placed in a regular pattern (a triangular area followed by a smooth area), with each triangle pointing towards the outside of the tube (see example in Figure 4). For other bottomless packaging, tactile warnings should be located on the operating surface.

3.4 The tactile warning (s) for small packaging should be located on the operating surface.

4. Durability of tactile symbols: Under normal operating conditions, warnings should maintain tactile sensation throughout the expected lifespan of the packaging

Contact number

Scan wechat